Q&A With Viega: Advantages of Press Technology in Plumbing

July 15, 2025

Seth Hiler, Technical Trainer at Viega, is joining us today to discuss key trends in residential plumbing, how modern press technology increases jobsite efficiency, and how builders can ensure a reliable, long-lasting installation.

With over a decade of hands-on experience in the plumbing trade, Seth is a Master Plumber who brings a wealth of practical knowledge spanning residential new construction, commercial projects and service plumbing. His background includes a four-year plumbing apprenticeship with Colorado State University’s construction services department and time as a lead service plumber where he helped significantly grow a plumbing and HVAC business.

This journey from apprentice to Master Plumber gives him a unique, ground-level perspective on the challenges builders and their trade partners face, and a deep understanding of how the right system solution can impact a project’s efficiency, reliability and profitability.

Our question-and-answer session is transcribed below.

To start our discussion, let's talk about how homebuyers are increasingly focused on sustainability and efficiency. In new home construction, what trends are you seeing in plumbing systems to address the demand for water and energy conservation?

Hiler: With a proven track record of reliability, efficiency and durability, PEX has become the go-to plumbing material for residential new construction, replacing copper and CPVC. This shift allows for more efficient installation methods that directly address conservation. For example, you have the option of running continuous lengths of tubing to reduce fittings in concealed spaces or using 3/8” tubing to improve hot water delivery speed, which conserves both water and energy. Additionally, parallel distribution systems like the ManaBloc® and MiniBloc® offer individual fixture isolation, further enhancing control and efficiency.

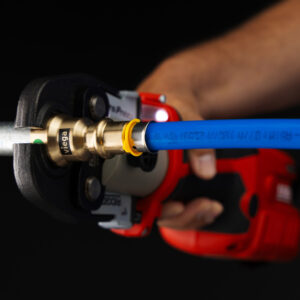

That leads perfectly into Viega’s press technology. For builders who aren’t familiar, can you explain what makes this system different and where it’s used?

Hiler: The huge benefit of using Viega is the comprehensive Viega System Solution. We offer solutions for nearly every need, from our PureFlow® PEX to our ProPress® for copper and stainless-steel tube sizes and MegaPress® for iron pipe. In a typical home, you could use ProPress off the water main, PureFlow PEX feeding the house, and MegaPress on the gas line — all while using the same tool and carrying one manufacturer’s warranty for the entire system. Our PureFlow PEX fittings come with a factory-installed stainless-steel ring, so contractors don’t need to purchase or manage additional parts like with other systems. A secure, permanent-press connection is made in less than 10 seconds.

Viega residential piping systems deliver whole-home solutions that keep projects on schedule and under budget. Viega is on the HomeSphere program and HomeSphere builders are eligible for rebates. Visit the Viega brand page for more information.

As you mention earlier, PEX is often a go-to material in new construction. To give builders assurance in the installation, what are the key design features of the Viega PureFlow system – like Smart Connect® – that create a solid, pressure-test-ready connection right away?

Hilger: Assurance in our system starts with the material itself. Viega’s PureFlow PEX carries a PEX5306 rating, the highest rating currently obtainable per ASTM F876, which gives the tubing the highest possible resistance to chlorine and UV damage, along with the highest rating for hydrostatic design stress. Our PureFlow fittings come pre-assembled to reduce headaches in the field and are made of Radel® R, a high-performance thermoplastic that is highly resistant to cracking and breaking. For ultimate peace of mind during installation, our patented Smart Connect® Technology allows any unpressed connection to be easily identified during a standard, low-pressure water or air test.

"All of Viega’s PureFlow Press fittings come pre-assembled to reduce headache in the field and when ordering product, as well as taking up less space when being stored."

Drilling down on jobsite efficiency, how does Viega’s press technology help contractors work faster, both in terms of ensuring a secure installation and simplifying the tools they need for the job?

Hiler: Jobsite efficiency comes from a combination of speed and simplicity. A contractor can use the same power tool for Viega PEX Press as they do for our ProPress and MegaPress metal systems, just by changing the jaws. Each connection takes only 5-15 seconds, and the system can be pressure tested immediately after the connections are made. Furthermore, because every Viega PEX fitting has a factory-installed stainless-steel ring, there's no need to carry separate inventory for rings, which simplifies both material management and installation.

The skilled labor shortage continues to be a major challenge. How does Viega’s solutions help builders overcome this, both in terms of the quick learning curve for contractors and the way the tooling ensures a confident install?

Hiler: The skilled labor shortage is a very real issue, and our system is designed to address it directly. Safe, reliable, consistent connections are what Viega’s product is designed for. By following a few very simple installation steps, any contractor can achieve a secure connection, which helps overcome gaps in experience. While the system is intuitive, training is still very important, and Viega is heavily invested in it. We offer training on-site, virtually, and in our state-of-the-art seminar centers to ensure anyone using our product feels completely comfortable and confident with the process.

"Safe, reliable, consistent connections is what Viega’s product

is designed for."

Callbacks can often be traced to variables in workmanship or jobsite conditions. How does Viega’s press system deliver a more consistent and repeatable installation that isn’t affected by climate, whether it's below freezing or extremely hot?

Hiler: Viega press is a purely mechanical connection, making it inherently consistent and weather resistant — the heat or the cold will not affect the quality of the connection. With certain other PEX connection methods, installers have to wait an "appropriate amount of time" for the pipe to constrict and form a seal, a wait time that varies with temperature. With Viega PureFlow, that is not an issue; you can Press-Test-Go. As an added layer of quality control, our fittings are designed to be easily identified if unpressed during a pressure test, ensuring every connection is secure before the walls are closed up.

With supply chain issues being a constant concern, how is Viega positioned to ensure reliable product delivery to builders in the U.S.?

Hiler: Viega is heavily invested in the North American market, from manufacturing to training and support. All Viega PureFlow PEX tubing and poly fittings are manufactured in McPherson, Kansas, which allows us complete control over our product quality and availability. We are expanding that investment with a new, state-of-the-art manufacturing facility in Ohio to support the increasing demand for our metal press fittings. To supplement this, we are also lucky to have heavy manufacturing capacity in Germany, so anything we are not able to manufacture domestically can be supported by those facilities.

Beyond the core piping system, what innovative solutions does Viega offer that can help a builder impress a homebuyer, like radiant floor heating or snow melt systems?

Hiler: We offer innovative systems that add significant luxury and comfort for a homebuyer. Our radiant heating and cooling systems provide unmatched comfort that is more energy-efficient than traditional forced-air, while our snow melt systems offer a high-end solution for safety and convenience. To make these advanced features easy for builders to implement, our complimentary Engineering Services team can design these intricate systems to fit the specific needs of the client. For builders with in-house design teams, we also provide all of our fittings in Revit® and other design software so they can use our actual fittings with the correct dimensions in their plans.

Why Viega

- Complete System Solution: A comprehensive system that allows builders to use a single tool and carry one manufacturer's warranty for PEX, copper and iron pipe applications throughout an entire project.

- Fast and Secure Press Technology: A simple, weather-resistant press connection that is made in seconds and is backed by patented Smart Connect® technology to ensure a reliable, test-ready installation.

- Quality Manufacturing in Kansas: Superior quality, from the highest-rated PEX tubing to robust fittings, is assured by manufacturing in McPherson, Kansas, and supported by complimentary engineering and training services.

Hear what Tony Caruso, Founder of AC Plumbing, in Cleveland, Ohio says about the value of Viega:

Interested in using Viega?

Rebates are available for both single-family and multifamily builders who join HomeSphere. Earn rebates through the HomeSphere Rebate Program, and check our full list of partners to see what other rebates you could be earning through our program.